推荐消息更多>>

推荐消息更多>>带你了解罗茨鼓风机转子热膨胀控制技术

- 来源:https://www.sdxinlujx.com/ 日期:2025-06-14 发布人:创始人

罗茨鼓风机作为一种容积式气体输送设备,其核心部件——一对同步反向旋转的转子,在运行过程中因机械摩擦、气体压缩及环境温度变化等因素,不可避免地会产生热膨胀现象。这种形变若未得到有效控制,将导致转子与机壳间隙缩小,引发效率下降、噪音增大甚至设备卡滞等故障。因此,如何科学控制转子热膨胀对设备稳定运行至关重要。

As a type of volumetric gas conveying equipment, the Roots blower's core components - a pair of synchronous and counter rotating rotors - inevitably experience thermal expansion during operation due to factors such as mechanical friction, gas compression, and environmental temperature changes. If this deformation is not effectively controlled, it will lead to a reduction in the gap between the rotor and the casing, resulting in decreased efficiency, increased noise, and even equipment jamming and other malfunctions. Therefore, it is crucial to scientifically control the thermal expansion of the rotor for the stable operation of the equipment.

材料选型与结构设计是控制热膨胀的基础。现代罗茨鼓风机转子多采用高强度铸铁或球墨铸铁材质,这类材料在保证刚性的同时,具备较低的热膨胀系数,可减少形变量。部分高端机型引入双金属复合转子,通过在转子工作面镶嵌抗摩擦合金层,既提升耐磨性,又利用不同材料的热膨胀差异形成自适应补偿效应。此外,转子型线设计采用渐开线或圆弧包络线,确保热膨胀后仍能维持理论间隙,避免啮合干涉。

Material selection and structural design are the basis for controlling thermal expansion. Modern Roots blower rotors are often made of high-strength cast iron or ductile iron materials, which not only ensure rigidity but also have a lower coefficient of thermal expansion, reducing deformation. Some high-end models introduce bimetallic composite rotors, which are embedded with anti friction alloy layers on the rotor working surface to improve wear resistance and form adaptive compensation effects by utilizing the thermal expansion differences of different materials. In addition, the rotor profile design adopts involute or circular arc envelope to ensure that the theoretical clearance can be maintained after thermal expansion and avoid meshing interference.

冷却系统优化是关键技术手段。鼓风机通常配备强制风冷或水冷装置,通过循环冷却介质带走转子及腔体热量。风冷系统采用轴流风机驱动空气流经散热翅片,加速热对流;水冷系统则在机壳内部设计螺旋冷却流道,利用水的比热容优势实现高效降温。部分机型创新采用热管技术,通过相变传热原理将转子端部热量快速传导至散热端,显著降低工作腔温度梯度。

Cooling system optimization is a key technical means. Blowers are usually equipped with forced air cooling or water cooling devices, which remove heat from the rotor and cavity through circulating cooling media. The air cooling system uses an axial flow fan to drive air through the heat dissipation fins, accelerating heat convection; The water cooling system is designed with spiral cooling channels inside the casing, utilizing the specific heat capacity advantage of water to achieve efficient cooling. Some models have innovatively adopted heat pipe technology, which rapidly transfers heat from the rotor end to the heat dissipation end through the principle of phase change heat transfer, significantly reducing the temperature gradient in the working chamber.

动态间隙补偿技术进一步提升了控制精度。通过在转子轴端设置弹性联轴器或液压补偿装置,实时监测轴向位移并自动调整轴承预紧力,使转子在热膨胀时仍能保持与机壳的恒定间隙。同时,智能温控系统集成温度传感器与变频器,根据实时温度数据动态调节鼓风机转速,在保证气量需求的前提下,避免过度升温引发的形变问题。

The dynamic gap compensation technology further improves the control accuracy. By installing an elastic coupling or hydraulic compensation device at the rotor shaft end, the axial displacement can be monitored in real time and the bearing preload can be automatically adjusted, so that the rotor can maintain a constant gap with the casing during thermal expansion. At the same time, the intelligent temperature control system integrates temperature sensors and frequency converters to dynamically adjust the blower speed based on real-time temperature data, avoiding deformation problems caused by excessive heating while ensuring air volume requirements.

运行维护规范同样不可忽视。安装阶段需严格控制转子与机壳的冷态间隙,预留合理的热膨胀余量;运行中定期检测轴承温度、振动及噪音参数,建立热膨胀趋势数据库;停机后避免立即关闭冷却系统,防止因温差骤变导致材料应力集中。

The operation and maintenance standards cannot be ignored either. During the installation phase, it is necessary to strictly control the cold clearance between the rotor and the casing, and reserve a reasonable amount of thermal expansion allowance; Regularly monitor bearing temperature, vibration, and noise parameters during operation, and establish a database of thermal expansion trends; Avoid immediately shutting down the cooling system after shutdown to prevent material stress concentration caused by sudden temperature differences.

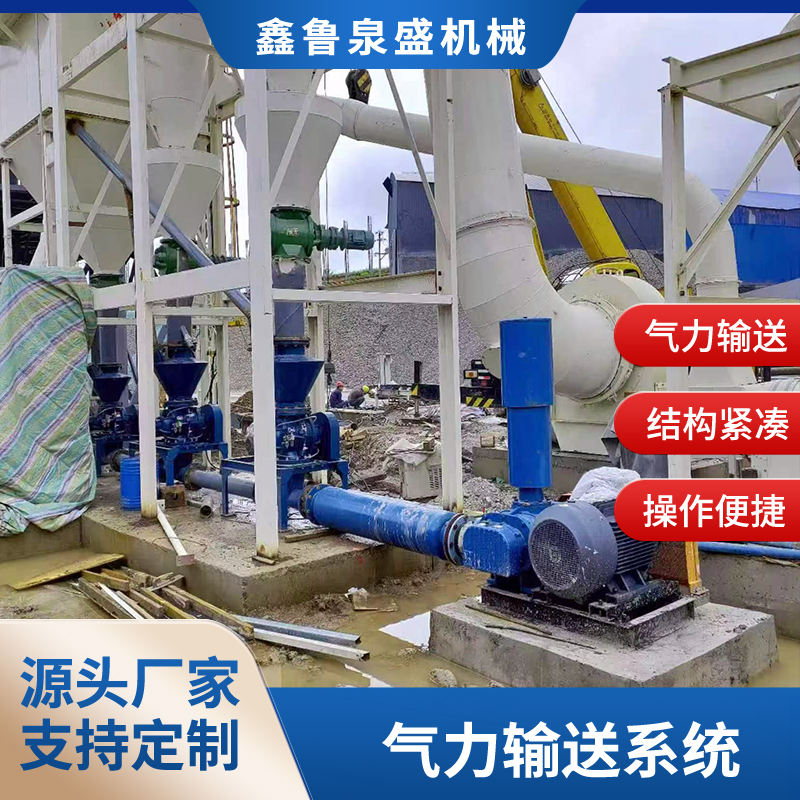

通过材料科学、热力学设计与智能控制的协同创新,罗茨鼓风机已形成多维度的转子热膨胀控制体系。这不仅延长了设备使用寿命,更保障了其在污水处理、气力输送等领域的稳定运行,为工业流程的连续性提供坚实支撑。

Through the collaborative innovation of materials science, thermodynamic design, and intelligent control, Roots blower has formed a multi-dimensional rotor thermal expansion control system. This not only extends the service life of the equipment, but also ensures its stable operation in fields such as sewage treatment and pneumatic conveying, providing solid support for the continuity of industrial processes.

本文由罗茨鼓风机友情奉献.更多有关的知识请点击:https://www.sdxinlujx.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from Roots blower For more information, please click: https://www.sdxinlujx.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a messag

Related news相关新闻

- 2025-10-25磁悬浮鼓风机:节能环保高效的气体输送设备

- 2025-10-24气力输送系统输送时物料易破碎怎么办?

- 2025-10-23旋转供料器在粉体输送中发挥中锁风下料、定量吹送的作用

- 2025-10-22仓泵在气力输送“心脏”中,扮演着重要角色

- 2025-10-21负压气力输送适合输送哪些类型的物料?

- 2025-10-20安全使用高压罗茨鼓风机必须要注意的8个方面

- 2025-10-18三叶罗茨风机经过频繁检修后,整理的常见故障原因和解决方法

- 2025-10-17高压罗茨鼓风机节能省电的方法和运行中的摩擦原因

- 2025-10-16高压罗茨风机 VS 离心风机,区别有哪些?

- 2025-10-15高压罗茨风机的产品介绍和适用场景

扫码微信沟通

扫码微信沟通