推荐消息更多>>

推荐消息更多>>工业除尘器中布袋除尘器的运行检查!

- 来源:https://www.sdxinlujx.com/ 日期:2024-01-22 发布人:创始人

工业除尘器中布袋除尘器试运转的好坏,直接影响其是否能投入正常运行,如处理不当,工业除尘器很可能会很快失去效用,因此,做好设备的试运转须细心和慎重。布袋除尘器一种干式滤尘装置。它适用于捕集细小、干燥、非纤维性粉尘。滤袋采用纺织的滤布或非纺织的毡制成,利用纤维织物的过滤作用对含尘气体进行过滤,当含尘气体进入袋式除尘器后,颗粒大、比重大的粉尘,由于重力的作用沉降下来,落入灰斗,含有较细小粉尘的气体在通过滤料时,粉尘被阻留,使气体得到净化。

The quality of the trial operation of the bag filter in industrial dust collectors directly affects whether it can be put into normal operation. If not handled properly, the industrial dust collector may quickly lose its effectiveness. Therefore, careful and cautious equipment trial operation is necessary. A bag filter is a dry dust filtering device. It is suitable for capturing small, dry, and non fibrous dust. The filter bag is made of textile filter cloth or non-woven felt, and uses the filtering effect of fiber fabric to filter the dusty gas. When the dusty gas enters the bag filter, the large and heavy particles of dust settle down due to gravity and fall into the ash hopper. When the gas containing fine and small dust passes through the filter material, the dust is blocked and the gas is purified.

工业除尘器中布袋除尘器试运行的检查事项

Inspection items for trial operation of bag filters in industrial dust collectors

布袋锅炉除尘器试运行时,应特别注意检查下列各点:

During the trial operation of the bag boiler dust collector, special attention should be paid to checking the following points:

1、滤袋的安装情况,在使用后是否有掉袋、松口、磨损等情况发生,投运后可目测烟囱的排放情况来判断。

1. The installation status of the filter bag, whether there is any bag dropping, loosening, wear, etc. after use, can be judged by visually observing the emission situation of the chimney after operation.

2、风机的旋转方向、转速、轴承振动和温度。

2. The rotation direction, speed, bearing vibration, and temperature of the fan.

3、要注意锅炉除尘器袋室结露情况是否存在,排灰系统是否畅通。防止堵塞和腐蚀发生,积灰严重时会影响主机的生产。

3. Pay attention to whether there is condensation in the bag chamber of the boiler dust collector and whether the ash discharge system is unobstructed. Prevent blockage and corrosion, as severe dust accumulation can affect the production of the host.

4、处理风量和各测试点压力与温度是否与设计相符。除尘器厂家除尘器的工作好坏,不仅直接影响到除尘系统的可靠运行,还关系到生产系统的正常运行、车间厂区和周边居民的环境卫生、风机叶片的磨损和寿命,同时还涉及有经济价值物料的回收利用问题。锅炉除尘器把粉尘从烟气中分离出来的设备。锅炉除尘器是锅炉及工业生产中常用的配套设备。它的功能是将锅炉燃料,燃烧排放烟气中的颗粒烟尘加以清除,从而大幅度降低排入大气层中的烟尘量,这是改善环境污染,提高空气质量的重要环保设备。

4. Check if the air volume and pressure and temperature at each testing point match the design. The operation of dust collectors by dust collector manufacturers not only directly affects the reliable operation of the dust removal system, but also relates to the normal operation of the production system, the environmental hygiene of the workshop and surrounding residents, the wear and service life of fan blades, and also involves the recycling and utilization of economically valuable materials. Boiler dust collector is a device that separates dust from flue gas. Boiler dust collector is a commonly used supporting equipment in boilers and industrial production. Its function is to remove particulate smoke and dust from boiler fuel and combustion emissions, thereby significantly reducing the amount of smoke and dust discharged into the atmosphere. This is an important environmental protection equipment for improving environmental pollution and air quality.

5、清灰周期及清灰时间的调整,这项工作是左右捕尘性能和运转状况的重要因素。清灰时间过长,将使附着粉尘层被清落掉,成为滤袋泄漏和破损的原因。如果清灰时间过短,滤袋上的粉尘尚未清落掉,就恢复过滤作业,将使阻力很快地恢复并逐渐增高起来,终影响其使用效果。

5. The adjustment of the cleaning cycle and cleaning time is an important factor affecting the dust collection performance and operating condition. If the cleaning time is too long, it will cause the attached dust layer to be removed, becoming the cause of filter bag leakage and damage. If the cleaning time is too short and the dust on the filter bag has not yet been removed, resuming the filtering operation will quickly restore the resistance and gradually increase, ultimately affecting its effectiveness.

工业除尘器中布袋除尘器试运行的检查事项

Inspection items for trial operation of bag filters in industrial dust collectors

两次清灰时间间隔称清灰周期,一般希望清灰周期尽可能的长一些,使除尘器能在经济的阻力条件下运转。因此,须对粉尘性质、含尘浓度等进行慎重地研究,并根据不同的清灰方法来决定清灰周期和时间,并在试运转中进行调整达到较佳的清灰参数。

The interval between two cleaning cycles is called the cleaning cycle, and it is generally hoped that the cleaning cycle will be as long as possible, so that the dust collector can operate under economic resistance conditions. Therefore, it is necessary to carefully study the properties of dust, dust concentration, etc., and determine the cleaning cycle and time based on different cleaning methods, and adjust them during trial operation to achieve optimal cleaning parameters.

在开始运转的时间,常常会出现一些事先预料不到情况,例如,出现异常的温度、压力、水分等将给新装置造成损害。除尘设备把粉尘从烟气中分离出来的设备,也叫除尘器或除尘设备。除尘设备是利用井下的除尘水管和压风管路,在水中加入的添加剂,引入风压,通过专用设备,完成一系列工艺流程,产生泡沫,通过分配器、喷头支架组件喷洒至尘源上。

At the beginning of operation, unexpected situations often occur, such as abnormal temperature, pressure, moisture, etc., which will cause damage to the new device. Dust removal equipment is a device that separates dust from flue gas, also known as a dust collector or dust removal equipment. The dedusting equipment is to use the dedusting water pipe and pressure air pipe under the shaft, add additives in the water, introduce air pressure, complete a series of process flows through special equipment, generate foam, and spray it to the dust source through the distributor and sprinkler support components.

本文由仓顶除尘器提供技术支持,更多的详细精彩内容请点击我们的网站https://www.sdxinlujx.com,我们将会全心全意为您提供满意的服务。

This article is supported by the technical support provided by the warehouse top dust collector. For more detailed and exciting content, please click on our website https://www.sdxinlujx.com We will wholeheartedly provide you with satisfactory service.

- 上一篇: 中央集尘系统负压除尘器的结构要注意什么?

- 下一篇: 布袋除尘器正压除尘和负压除尘的方式

Related news相关新闻

- 2025-10-25磁悬浮鼓风机:节能环保高效的气体输送设备

- 2025-10-24气力输送系统输送时物料易破碎怎么办?

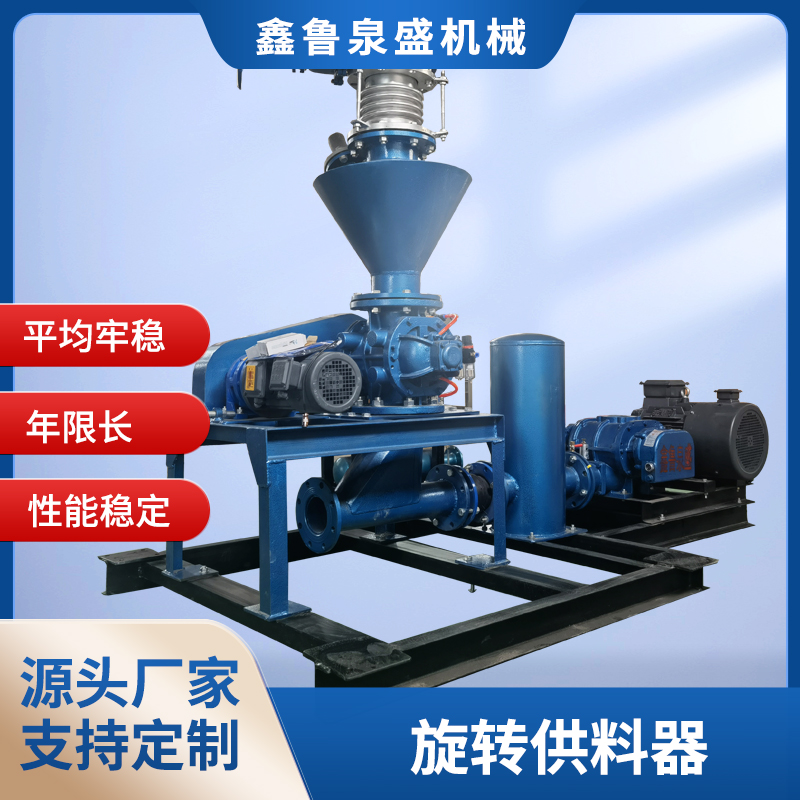

- 2025-10-23旋转供料器在粉体输送中发挥中锁风下料、定量吹送的作用

- 2025-10-22仓泵在气力输送“心脏”中,扮演着重要角色

- 2025-10-21负压气力输送适合输送哪些类型的物料?

- 2025-10-20安全使用高压罗茨鼓风机必须要注意的8个方面

- 2025-10-18三叶罗茨风机经过频繁检修后,整理的常见故障原因和解决方法

- 2025-10-17高压罗茨鼓风机节能省电的方法和运行中的摩擦原因

- 2025-10-16高压罗茨风机 VS 离心风机,区别有哪些?

- 2025-10-15高压罗茨风机的产品介绍和适用场景

扫码微信沟通

扫码微信沟通