推荐消息更多>>

推荐消息更多>>布袋除尘器正压除尘和负压除尘的方式

- 来源:https://www.sdxinlujx.com/ 日期:2024-01-25 发布人:创始人

布袋除尘器正压除尘和负压除尘的优缺点:(1)正压除尘系统,布袋除尘器 正压式(又称压入式)除尘器内部气体压力高于大气压力,正压式 布袋 除尘器引风机安装在除尘器含尘烟气进口端,在除尘器墙体内产生正压力,易将含尘或腐蚀物烟气导入除尘器,不易安装在室内,也不易处理毒性大的含尘烟气 。

The advantages and disadvantages of positive pressure dust removal and negative pressure dust removal of bag filter: (1) Positive pressure dust removal system. The positive pressure (also known as pressure in type) dust collector has a gas pressure higher than atmospheric pressure inside. The positive pressure bag filter's induced draft fan is installed at the inlet of the dust containing flue gas in the dust collector, generating positive pressure inside the dust collector wall, which easily leads the dust containing or corrosive flue gas into the dust collector and is not easy to install indoors, It is also difficult to handle highly toxic dusty smoke.

但含尘或腐蚀物烟气通过风机内部,容易对风机造成损伤及磨损;正压式袋式除尘器的特点是外壳结构简单轻便,密封性要求不高,造价低,且布置紧凑。

However, smoke containing dust or corrosive substances passing through the interior of the fan can easily cause damage and wear to the fan; The characteristics of positive pressure bag filter are simple and lightweight shell structure, low sealing requirements, low cost, and compact layout.

正压除尘系统中的除尘器应设置在通风机之后。其特点如下。

The dust collector in the positive pressure dust removal system should be installed after the ventilation fan. Its characteristics are as follows.

①由于除尘器设置在通风机后,含尘气体未经除尘器净化先流过通风机,通风机的叶轮和机壳极易遭粉尘磨损。因此正压除尘系统只适用于气体含尘浓度小于3g/m3,粉尘磨损性弱、力度小的情况。

① Due to the dust collector being installed behind the ventilation fan, the dusty gas flows through the fan before being purified by the dust collector, and the impeller and casing of the fan are easily worn by dust. Therefore, the positive pressure dust removal system is only suitable for situations where the gas dust concentration is less than 3g/m3, the dust wear is weak, and the force is small.

②由于除尘器处于通风机的正压段,不必考虑除尘器的漏风率,通风机电耗较低。

② Due to the fact that the dust collector is located in the positive pressure section of the ventilation fan, there is no need to consider the air leakage rate of the dust collector, resulting in lower mechanical and electrical consumption of the ventilation system.

③除尘器的维护结构简单,如正压袋式除尘器的维护结构不需要密封,只需采取防雨措施即可;设备制造与安装简便,造价低。

③ The maintenance structure of the dust collector is simple, for example, the maintenance structure of the positive pressure bag filter does not need to be sealed, only rainproof measures need to be taken; Equipment manufacturing and installation are simple and cost-effective.

④除尘器有一定的消声作用,通风机出口侧可不设消声器;有利节约除尘系统占地,减少初始投资。

④ Dust collectors have a certain degree of noise reduction effect, and silencers may not be installed on the outlet side of ventilation fans; Beneficial for saving space for dust removal systems and reducing initial investment.

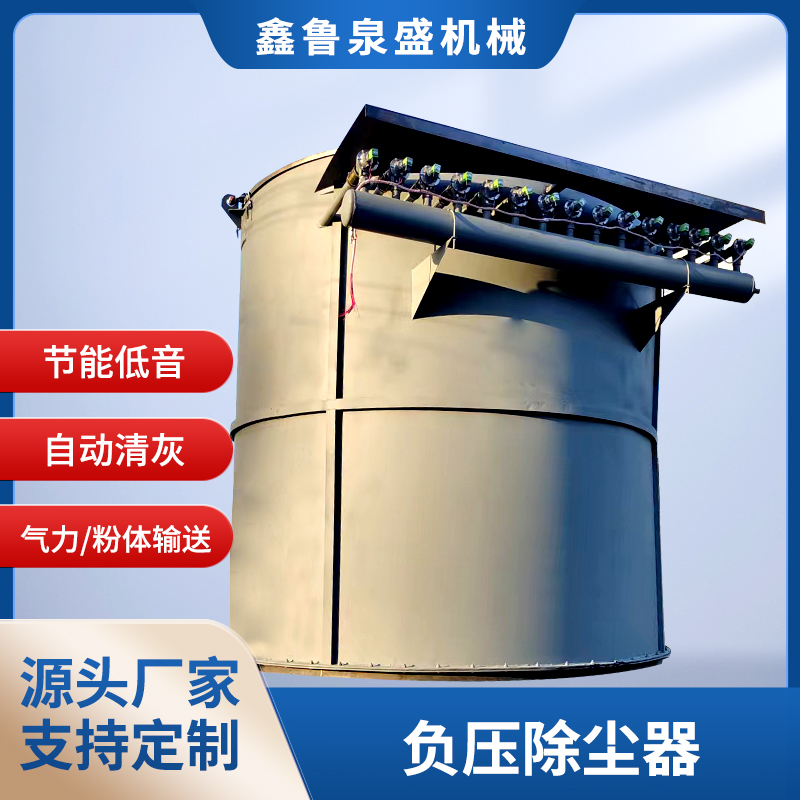

(2)负压除尘系统,布袋除尘器的 负压式(又称吸入式):负压式 布袋 除尘器引风机安装在除尘器净化气体出口端,通过负压将含尘或腐蚀物烟气引入除尘器内部进行净化,通过风机内部的为净化后气体。一般含尘浓度_过3g/m?,粒度较粗,磨琢性强,硬度大的粉尘均选用负压式。

(2) Negative pressure dust removal system, also known as suction type of bag dust collector: The negative pressure bag dust collector's induced draft fan is installed at the outlet of the purified gas in the dust collector, and the smoke containing dust or corrosive substances are introduced into the dust collector for purification through negative pressure. The purified gas is obtained through the fan. General dust concentration_ Over 3g/m?, Dust with coarse particle size, strong grinding ability, and high hardness is selected as negative pressure type.

负压式 布袋 除尘器的突出优点是可使风机免受粉尘磨损,但对外壳的结构强度和密闭性要求高。排放的气体有强腐蚀性,应该选择负压袋式除尘器,这样腐蚀性气体好控制,不易泄漏,好稀释。脉冲除尘器按过滤方向:内滤式、外滤式,按进气口位置:分下进风布袋除尘器和上进风布袋除尘器。

The prominent advantage of negative pressure bag filter is that it can protect the fan from dust wear, but it requires high structural strength and airtightness of the shell. The emitted gas has strong corrosiveness, and a negative pressure bag filter should be selected. This way, the corrosive gas is easy to control, not easy to leak, and easy to dilute. The pulse dust collector is divided into two types according to the filtering direction: internal filtering and external filtering. According to the position of the air inlet, it is divided into a lower inlet bag dust collector and an upper inlet bag dust collector.

负压除尘系统中的除尘器应设置在通风机之前。其特点如下。

The dust collector in the negative pressure dust removal system should be installed before the ventilation fan. Its characteristics are as follows.

①由于除尘器设置在通风机前,大大降低了气体的含尘浓度,使通风机的受磨损程度显著减低,运行寿命增长,因此负压除尘系统可以处理初始浓度高的含尘气体。

① Due to the dust collector being installed in front of the ventilation fan, the dust concentration of the gas is greatly reduced, resulting in a significant reduction in the wear and tear of the ventilation fan and an increase in its operating life. Therefore, the negative pressure dust removal system can handle high initial concentration of dust containing gas.

②由于除尘器和管道处于通风机的负压段,容易吸入空气,产生漏风(漏风率可达5%~10%),因此加大了通风机的风量,增加了电耗。

② Due to the fact that the dust collector and pipeline are located in the negative pressure section of the ventilation fan, it is easy to inhale air and cause air leakage (with a leakage rate of 5% to 10%), which increases the air volume of the ventilation fan and increases power consumption.

对于选用正压除尘系统还是负压除尘系统,应该具体视除尘气体的特点而定。

Whether to choose a positive pressure dust removal system or a negative pressure dust removal system should depend on the characteristics of the dust removal gas.

常用的除尘设备有一下几种,机械式除尘设备,洗涤式除尘设备,过滤式除尘设备,静电除尘设备,磁力除尘 设备,下面我们具体来分项介绍一下。

There are several commonly used dust removal equipment, including mechanical dust removal equipment, washing dust removal equipment, filtering dust removal equipment, electrostatic dust removal equipment, and magnetic dust removal equipment. Below, we will introduce them separately.

1、机械式除尘设备:机械式除尘设备包括重力除尘设备、离心除尘设备和惯性除尘设备。

1. Mechanical dust removal equipment: Mechanical dust removal equipment includes gravity dust removal equipment, centrifugal dust removal equipment, and inertial dust removal equipment.

2、洗涤式除尘设备:洗涤式除尘设备包括水浴式除尘设备、泡沫式除尘设备,文丘里管除尘设备、水膜式除尘设备 等。

2. Washing dust removal equipment: Washing dust removal equipment includes water bath dust removal equipment, foam dust removal equipment, Venturi tube dust removal equipment, water film dust removal equipment, etc.

3、过滤式除尘设备:过速式除尘设备除尘机理类似于口置,是通过过滤材料对空气中的飞灰颗粒进行机械拦截来实 现的,另先收到的飞灰颗粒在滤料表面形成了一层粘稠的稳定的灰层,称为滤饼或虑床,它又起了很好的过滤作 用。

3. Filter type dust removal equipment: The dust removal mechanism of the over speed dust removal equipment is similar to that of an oral device, which is achieved by mechanically intercepting fly ash particles in the air through filter materials. In addition, the first received fly ash particles form a thick and stable ash layer on the surface of the filter material, called a filter cake or filter bed, which plays a good filtering role.

4、静电除尘设备:静电除尘设备的工作原理是烟气通过电除尘设备主体结构前的烟道时,使其烟尘带正电荷,然后 烟气进入设置多层阴极板的电除尘设备通道。

4. Electrostatic dust removal equipment: The working principle of electrostatic dust removal equipment is that when the smoke passes through the flue in front of the main structure of the electrostatic dust removal equipment, the smoke carries a positive charge, and then the smoke enters the channel of the electrostatic dust removal equipment with multiple cathode plates.

5、磁力除尘设备:磁力除尘设备原理是利用导电线圈产生磁场,吸附磁性颗粒,主要用于钢铁等工业废气。

5. Magnetic dust removal equipment: The principle of magnetic dust removal equipment is to use conductive coils to generate a magnetic field and adsorb magnetic particles, mainly used for industrial waste gas such as steel.

很常用的除尘设备就是布袋除尘设备和滤简除尘设备 布袋除尘设备主要布袋除尘设备(袋式除尘器、布袋除尘器)的工作机理是含尘烟气通过过滤材料,尘粒被 过滤下来,过滤材料捕集粗粒粉尘主要靠惯性碰撞作用,捕集细粒粉尘主要靠扩散和筛分作用。布袋除尘设备除尘 效果的优劣与多种因素有关,但主要取决于滤料。布袋除尘器的滤料就是合成纤维、天然纤维或玻璃纤维织成的布 或毡。根据需要再把布或毡缝成圆简或扁平形除尘滤袋。根据烟气性质,选择出适合于应用条件的滤料。通常,在 烟气温度低于120℃,要求滤料具有耐酸性和耐久性的情况下,常选用涤纶绒布和涤纶针刺毡;在处理高温烟气 (<250C)时,主要选用石墨化玻璃丝布。

The commonly used dust removal equipment includes bag dust removal equipment and filter dust removal equipment. The main working mechanism of bag dust removal equipment (bag filter, bag dust collector) is that the dust containing flue gas passes through the filter material, and the dust particles are filtered out. The filter material mainly captures coarse dust particles through inertial collision, while capturing fine dust particles mainly relies on diffusion and screening. The dust removal effect of bag dust removal equipment is related to various factors, but mainly depends on the filter material. The filter material of a bag filter is a cloth or felt woven from synthetic fibers, natural fibers, or glass fibers. Sew the cloth or felt into round or flat dust removal filter bags as needed. Select filter media suitable for application conditions based on the properties of the flue gas. Usually, when the flue gas temperature is below 120 ℃ and the filter material is required to have acid resistance and durability, polyester velvet cloth and polyester needle punched felt are often used; When dealing with high-temperature flue gas (<250C), graphite glass fiber cloth is mainly used.

- 上一篇: 布袋除尘器正压除尘和负压除尘的方式

- 下一篇: 除尘器正压和负压区别在哪?

Related news相关新闻

- 2025-10-25磁悬浮鼓风机:节能环保高效的气体输送设备

- 2025-10-24气力输送系统输送时物料易破碎怎么办?

- 2025-10-23旋转供料器在粉体输送中发挥中锁风下料、定量吹送的作用

- 2025-10-22仓泵在气力输送“心脏”中,扮演着重要角色

- 2025-10-21负压气力输送适合输送哪些类型的物料?

- 2025-10-20安全使用高压罗茨鼓风机必须要注意的8个方面

- 2025-10-18三叶罗茨风机经过频繁检修后,整理的常见故障原因和解决方法

- 2025-10-17高压罗茨鼓风机节能省电的方法和运行中的摩擦原因

- 2025-10-16高压罗茨风机 VS 离心风机,区别有哪些?

- 2025-10-15高压罗茨风机的产品介绍和适用场景

扫码微信沟通

扫码微信沟通